We are interested in three research levels, which contain process optimization, device development, and system integration.

In process level, we are interested in two research topics in recent years.

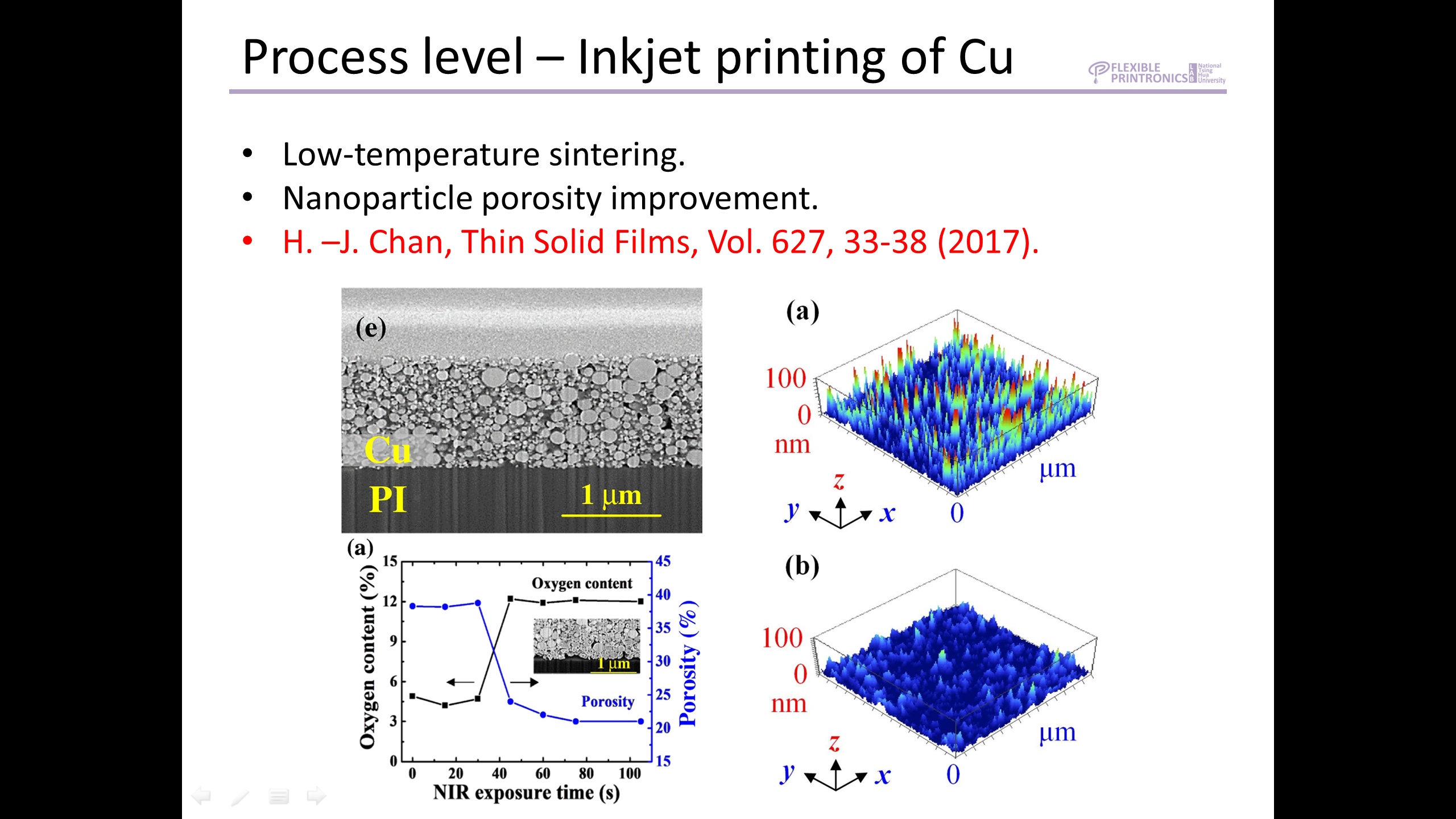

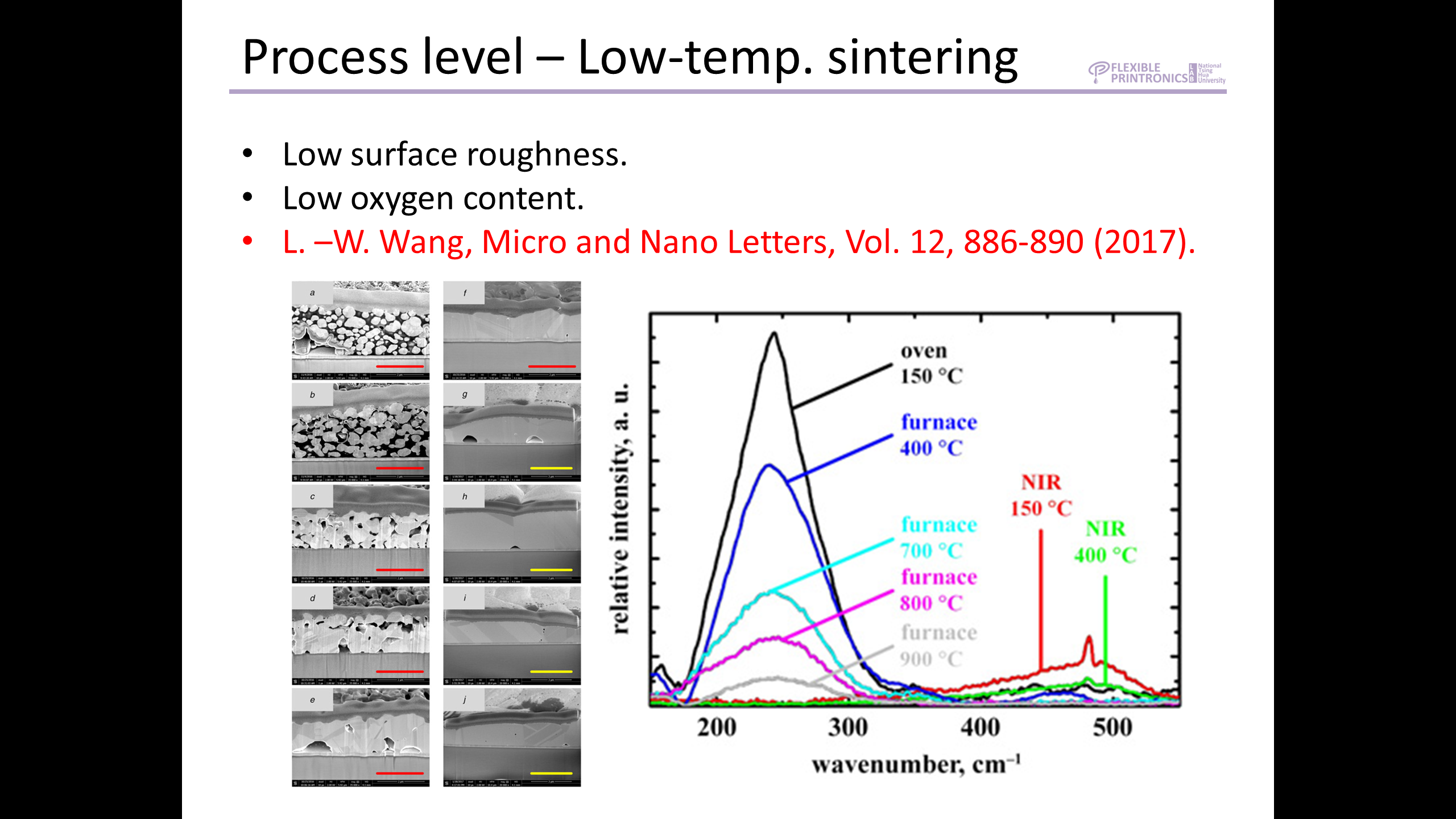

The first topic is the optimization of solution-processed organic light emitting diode(OLED), in which low-temperature particle sintering was achieved. Successful examples include copper nanoparticles with optimized oxygen content, porosity, and electrical conductivity achieved by near infrared exposure. Its 10 nm surface roughness ensures application eligibility with good adhesion in ASTM standard. Another example is silver microparticles that show close-to-bulk electrical resistivity and material density after rapid thermal annealing, which show application potentials in electrodes of printed OLEDs.

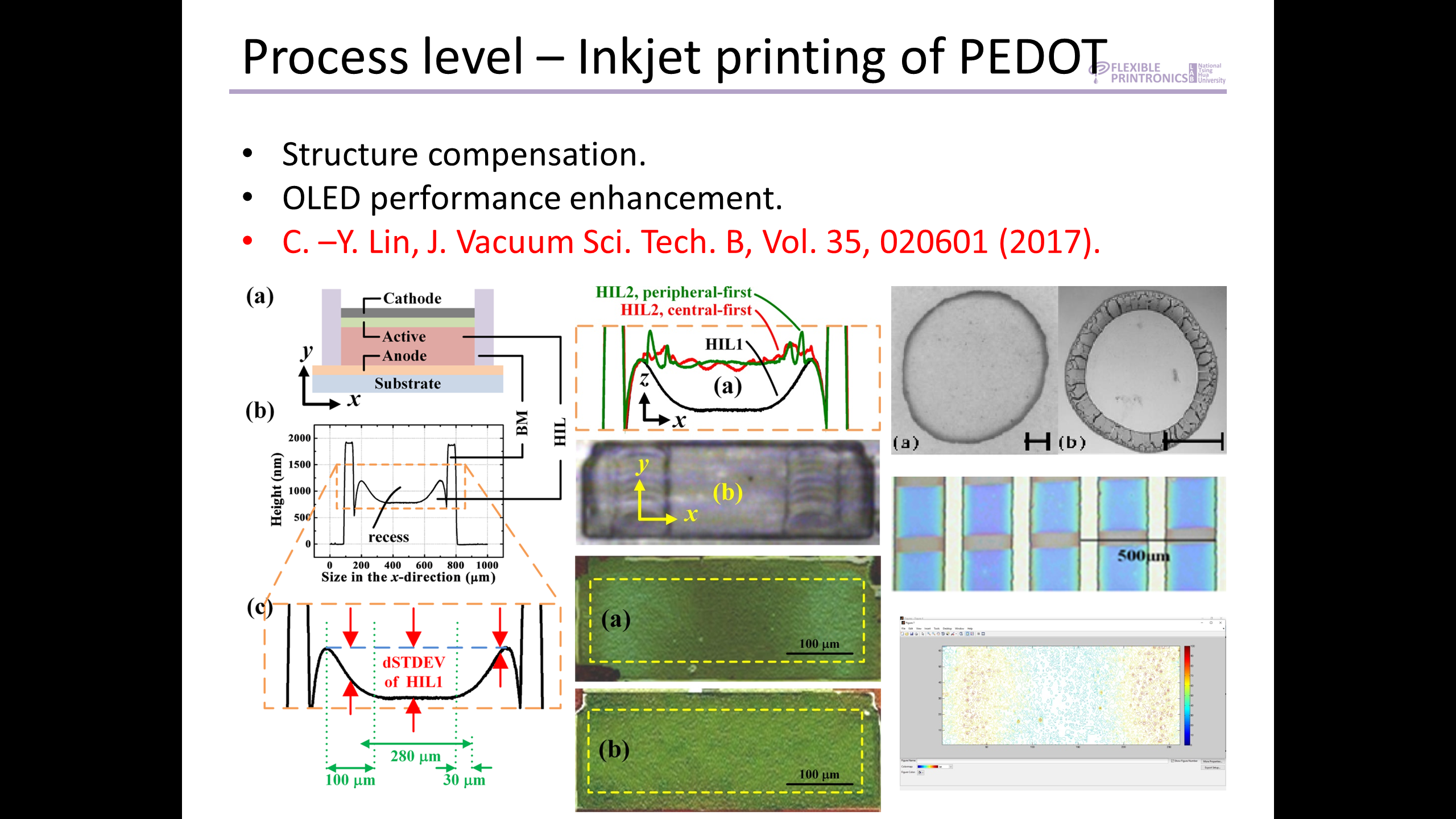

Also, the structural compensation of coffee-ring structure generated during inkjet printing was accomplished, resulting uniform current density in OLED. By precise calculating and supplying additional but required solid content to the dried pre-layer, the recess of the coffee-ring structure was flattened. Not only the current density and the light intensity of OLED were quantified, but also its uniformity was scientifically evaluated by image operation on the lit OLED.

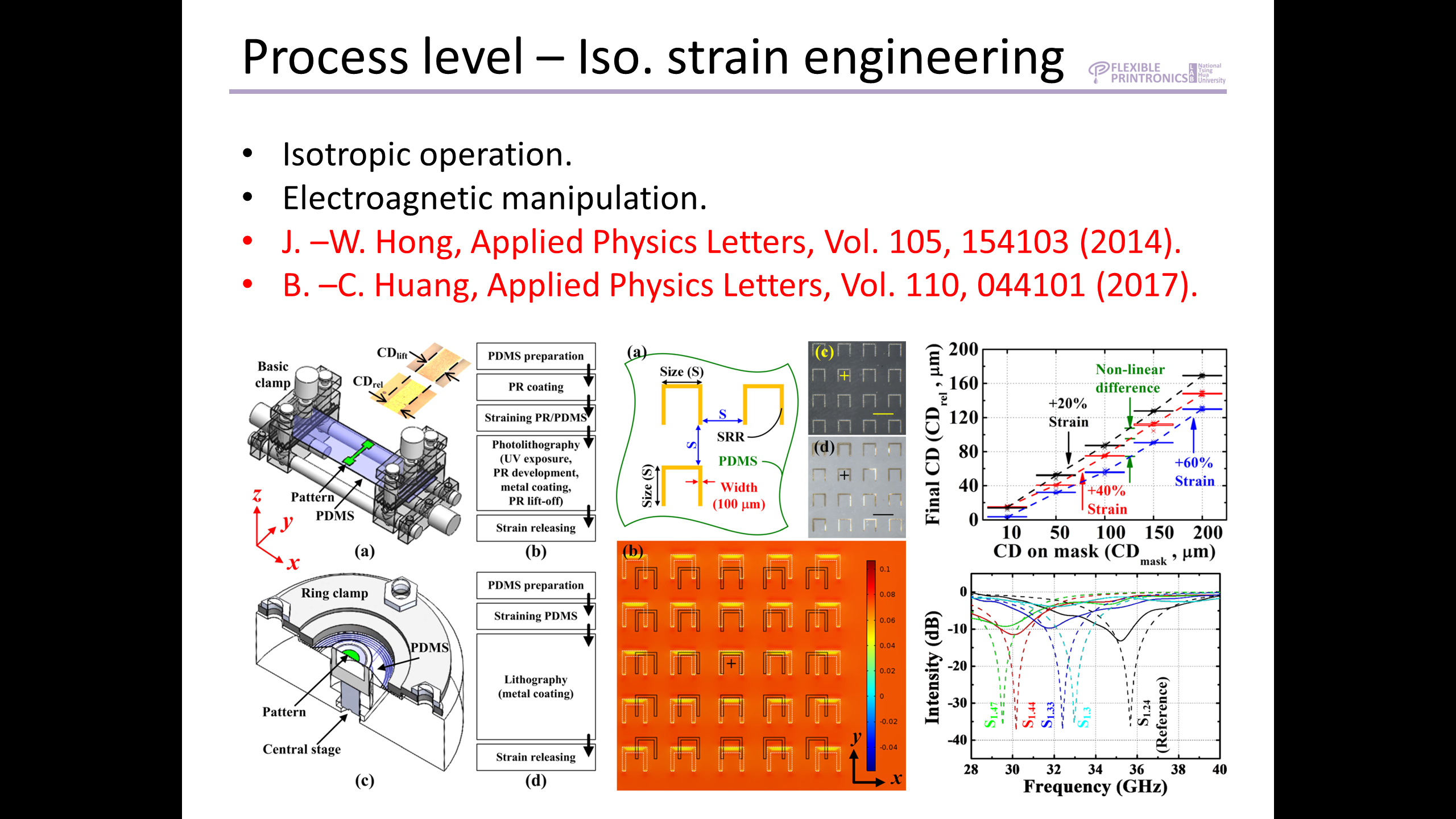

The second topic is the fabrication of microstructural metamaterial on elastomer using inkjet printing. With correct control of the drop space, printed patterns show good integrity for deformations under reasonable extent of strains. This metamaterial modulates the frequency and intensity of coupled electromagnetic energy in military applications such as an active frequency-selective surface (AFSS), in which modulations are realized by the natural movement of soldier instead of additional power sources.